Advanced Materials

TECHNOLOGY APPLIED TO THE TECHNICAL CERAMICS

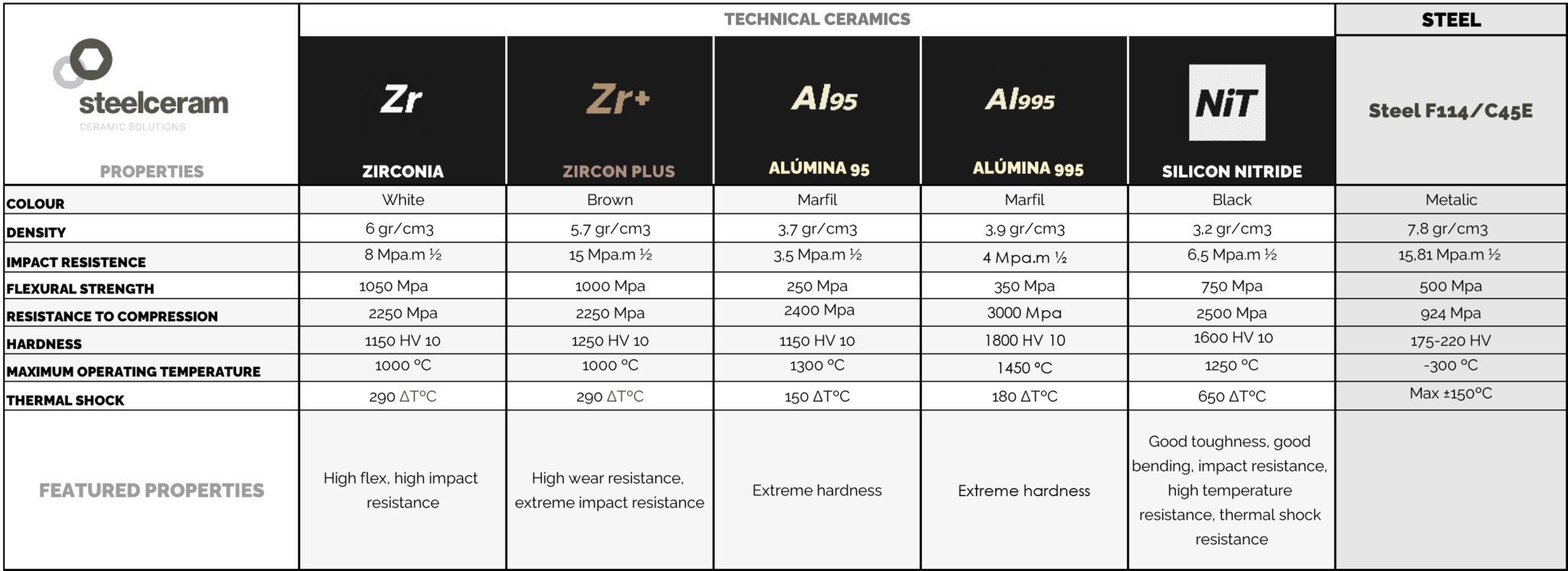

Our materials are outstanding for their extreme hardness and non-wearing capacity, low electrical and thermal conductivity, chemical resistance, resistance to abrasive materials and for their high biocompatibility.

Zirconia Steelceram

Zirconia is a ceramic with a unique crystalline structure that makes it extremely resistant. This structure allows it to prevent the propagation of cracks through the core, providing excellent mechanical resistance and extreme hardness. As most other ceramics, it does not conduct electricity, and the maximum operating temperature is also very high.

Characteristics

Color: White

Density: 6 gr/cm3

Impact resistance:: 8 Mpa.m 1/2

Flexural strength: 1050 Mpa

Compression Resistance: 2250 Mpa

Hardness: 1150 HV 10

Maximum operating temperature: 1000 ºC

Thermal shock resistance: 290 ΔTºC

Outstanding Properties

High flexural strength

High impact resistance

Zircon Plus Steelceram

Zircon plus is our new material that improves the properties of our base zirconia for more challenging applications where impact resistance and enhanced service life are required. The ceramic composition has been optimised to achieve longer service life in centering pins that offer more resistant to shocks and wear.

Characteristics

Color: Brown

Density: 5,7 gr/cm3

Impact resistance: 15 Mpa.m 1/2

Flexural strength: 1000 Mpa

Compression Resistance: 2250 Mpa

Hardness: 1250 HV 10

Maximum operating temperature: 1000 ºC

Thermal shock resistance: 290 ΔTºC

Outstanding Properties

High wear resistance

Extreme impact resistance

Alumina 95 Steelceram

Alumina 95 or Aluminium oxide is a ceramic with a crystalline structure which makes it extremely hard. Compared to zirconia has a higher hardness but lower resistance to bending, that means it is a more fragile material. This alumina is a cheaper option than Al995 for less demanding applications.

Characteristics

Color: Ivory

Density: 3,7 gr/cm3

Impact resistance: 3,5 Mpa.m 1/2

Flexural strength: 250 Mpa

Compression Resistance: 2400 Mpa

Hardness: 1150 HV 10

Maximum operating temperature: 1300 ºC

Thermal shock resistance: 150 ΔTºC

Outstanding Properties

Extreme hardness

Alumina 995 Steelceram

Alumina 995 is a ceramic with a crystalline structure that makes it extremely hard. Compared to zirconia has a higher hardness but lower resistance to bending, that means it is a more fragile material. This alumina is an option with improved mechanical properties compared to Al95.

Characteristics

Color: Ivory

Density: 3,9 gr/cm3

Impact resistance: 4 Mpa.m 1/2

Flexural strength: 350 Mpa

Resistance compression: 3000 Mpa

Hardness: 1800 HV 10

Maximum operating temperature: 1450 ºC

Thermal shock resistance: 180 ΔTºC

Outstanding Properties

Extreme hardness

Zirconia toughened alumina Steelceram

Zirconia toughened with alumina is a mixture of the two materials that achieves the properties of alumina with enhanced flexural strength by losing hardness. It is used especially in medical applications that require biocompatibility

Characteristics

Color: White

Density: 4,1 gr/cm3

Impact resistance: 4,4 Mpa.m 1/2

Flexural strength: 450 Mpa

Compression Resistance: 2500 Mpa

Hardness: 1500 HV 10

Maximum operating temperature: 1300 ºC

Thermal shock resistance: 180 ΔTºC

Outstanding Properties

Biocompatibility

Silicon nitride Steelceram

Silicon nitride is the lightest technical ceramic from our catalogue. It stands out for its high resistance to thermal shock, which makes it an excellent choice for applications subjected to high temperatures. Its mechanical properties are better than those of Zirconia in terms of hardness, losing resistance to bending.

Characteristics

Color: Black

Density: 3,2 gr/cm3

Impact resistance: 6,5 Mpa.m 1/2

Flexural strength: 750 Mpa

Compression Resistance: 2500 Mpa

Hardness: 1600 HV 10

Maximum operating temperature: 1250 ºC

Thermal shock resistance: 650 ΔTºC

Outstanding Properties

Good hardness

Good flexion

Impact resistance

Resistance to high temperatures

Resistance to thermal shock

Zirconia with magnesia Steelceram

Magnesia-stabilised zirconia is a combination specially designed for applications where water and high temperatures are combined. Their mechanical properties are very similar to zirconia in terms of abrasion and resistance to bending.

Characteristics

Color: Yellow

Density: 5,7 gr/cm3

Impact resistance: 6,5 Mpa.m 1/2

Flexural strength: 400 Mpa

Compression Resistance: 1600 Mpa

Hardness: 1200 HV 10

Maximum operating temperature: 1000 ºC

Thermal shock resistance: 280 ΔTºC

Outstanding Properties

Chemical Resistance