Where to find the Ceramic Plunger Woma 1502

In the world of extreme industrial cleaning, few parts work under as much pressure – literally and figuratively – as the pistons of a WOMA pump. And yet, the WOMA 1502 ceramic piston rarely gets the attention it deserves. Often relegated to a “minor spare part” category, this part is actually the hidden heart that withstands abrasion, heat, chemicals and a relentless pace of work. Here’s a thought: what if stopping thinking of it as a simple consumable was the first step towards a structural improvement in your maintenance system? This article proposes to change the technical perspective on the ceramic piston: not as a substitute, but as a strategic decision.

What is a ceramic piston and why is it used in WOMA pumps?

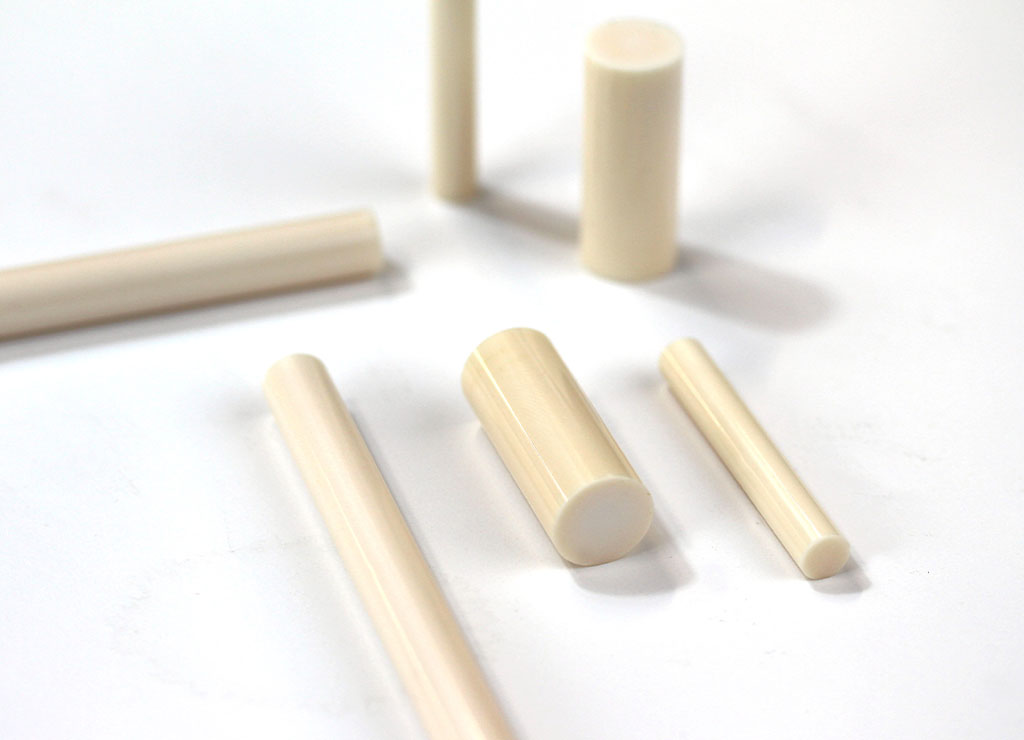

The WOMA 1502 ceramic piston is not simply a replacement part: it is an engineered solution designed to meet the extreme challenges encountered in high-pressure industrial cleaning systems. WOMA pumps operate by displacing water at pressures in excess of 1000 bar, and do so through a piston system that demands extreme precision in movement and constant resistance to friction, heat and chemicals.

The piston, in this context, is the heart of the system. If it loses its shape, even microscopically, the pump loses hydraulic efficiency, turbulence is generated, effective flow rates drop and maintenance times increase. This is where technical ceramics – and in particular alumina – offer real advantages over steel or materials with surface coatings. Its hardness prevents irregular wear, its thermal stability prevents deformation under temperature, and its chemical inertness makes it immune to recycled water, aggressive detergents or abrasive particles in suspension.

In addition, the non-metallic nature of ceramic eliminates common problems such as internal corrosion or unwanted heat transfer. Instead of simply replacing a worn piston, incorporating a ceramic piston means longer operating cycles and fewer mechanical interventions. In pumps such as the WOMA 1002, 1502 or 1503, this choice translates directly into reduced risk of failure and increased equipment profitability.

Advantages of the ceramic piston over other solutions

In most workshops or industrial plants, spare parts are evaluated by price and availability. But in the case of a high-pressure pump piston, this logic can be expensive. The most common alternatives – chrome-plated or ceramic-coated pistons – often appear more economical, but their behavior over time reveals the opposite. Chrome plating tends to microcrack with intensive use, leading to accelerated wear, leaks and eventually unscheduled shutdowns. The ceramic coating, although more resistant, wears unevenly: once the surface layer disappears, the piston loses its functional properties and must be completely replaced.

The solid ceramic piston, on the other hand, has a progressive, uniform and predictable wear, which makes it possible to plan maintenance more accurately and avoid sudden failures. Moreover, because it does not release metal particles or rust, it helps to maintain the purity of the hydraulic system. In WOMA pumps subjected to extreme use, such as tank cleaning or high-pressure waterjetting, this translates into longer life, fewer interventions and stable performance over time.

Choosing a ceramic piston means not only opting for a more resistant material, but also rethinking the maintenance approach: moving from a reactive logic to a preventive and strategic logic. In this paradigm shift, ceramics is no longer an “extra” but a fundamental ally of operational efficiency.

Sectors where WOMA pumps with ceramic pistons are used

Ceramic pistons are used in sectors where high pressure cleaning is critical: petrochemical, marine, energy, mining and industrial maintenance. There, the durability and resistance of the ceramic piston guarantees safe, continuous and efficient operations even under extreme conditions of pressure, temperature and abrasion.

Where to find reliable ceramic spare parts for high pressure pumps?

Finding a ceramic piston for WOMA 1502 pumps that combines dimensional accuracy, extreme strength and operational reliability should not be a matter of luck, but of technical judgment. The market abounds with generic or adapted options that may seem adequate, but often fail in the details: imprecise tolerances, low-density ceramics or poorly designed assemblies that compromise the system’s tightness. Going with a specialized manufacturer like Steelceram means having access to pistons made with high-purity technical ceramics, quality control at every stage of the process and the ability to customize to specific drawings or needs. Moreover, by dealing directly with the manufacturer, traceability, technical support and the possibility of improving the original design by incorporating solutions such as interchangeable metal shafts or optimized geometries are guaranteed. More than a spare part, it is a tailor-made solution for those who understand that reliability and precision cannot be improvised.

Beyond replacement, an investment in performance and durability

The WOMA 1502 ceramic piston is not just a replacement, but a strategic decision that directly impacts efficiency and operational continuity. Choosing technical ceramics means opting for less downtime, longer service life and more predictable maintenance. In environments where every hour counts, investing in quality is not an expense, but a smart way to protect overall system performance.