Do you need custom-made cordierite parts? Steelceram is the solution.

Custom cordierite parts manufactured by Steelceram offer a highly specialized ceramic solution for demanding industrial applications. Thanks to its unique properties, such as low thermal conductivity and excellent thermal shock resistance, cordierite is positioned as a key material in environments where thermal and electrical stability is essential.

In this article, we explore what makes this material a preferred technical choice, what type of parts Steelceram manufactures and how we accompany our customers from design to production. If you are looking for a durable, precise alternative adapted to your process, this content can guide you.

- What is cordierite and why is it used in demanding industrial environments?

Cordierite is a silicate ceramic material with a composition based on magnesium, aluminum and silicon, especially valued for its low coefficient of thermal expansion, which makes it extremely resistant to thermal shocks. This property, combined with its low thermal conductivity and good electrical insulation, allows its use in a wide variety of industries.

It performs exceptionally well in environments where there are rapid temperature changes, such as in furnaces, heating element systems, or industrial heating devices. In addition, its relatively light weight and good dimensional stability make it ideal for structural support components subjected to repeated thermal cycling.

Compared to other ceramic materials such as alumina or zirconia, cordierite does not stand out for its hardness or mechanical strength, but it excels in thermal applications where these properties are not a priority. Compared to silicon nitride, for example, it has a much more competitive cost, which makes it an excellent choice for insulating parts that are not subject to high mechanical stresses.

In summary, its thermal behavior positions it as a technical material of choice in applications where heat resistance, insulation and dimensional stability at elevated temperatures are a priority.

- Steelceram as a manufacturer of cordierite parts: expertise, precision and customization

At Steelceram we do not work with standard parts. Each tailor-made cordierite component we manufacture is born from a specific technical need. We specialize in manufacturing parts according to drawings, CAD designs or even from physical samples, adapting to complex geometries and specific thermal or electrical requirements.

Our experience in CNC machining of technical ceramics allows us to work with tight tolerances and finishes that guarantee a perfect fit in the final assembly. For geometries that require it, we use casting molds that allow us to manufacture parts in small and medium series with a high degree of repeatability and precision. In later stages, we perform grinding, drilling or milling operations to meet more demanding specifications.

We accompany the customer from the very beginning: from the selection of the most suitable type of cordierite (open porosity, dense or with special granulometry), to the validation of prototypes. We know that in sectors such as thermal, electronic or resistance, a poorly dimensioned part can compromise the entire system. Therefore, at Steelceram we understand that the key is not only to manufacture, but to co-design technical ceramic solutions adapted to each project.

4. Types of cordierite parts we manufacture at Steelceram

4.1 Parts for electrical resistors and inductors

We manufacture cordierite supports, insulators and structural elements used in electrical resistors, cartridge heaters and high temperature inductors. These parts act as thermal and electrical insulators, maintaining their shape and function even after thousands of thermal cycles. They are essential components to ensure the safety and efficiency of the heating system.

4.2 Supports and guides for industrial furnaces

We develop cordierite parts that serve as trays, supports, spacers or guides inside industrial furnaces. These parts withstand mechanical loads at high temperatures without deformation, which allows maintaining the alignment and stability of the products in baking, sintering or continuous heat treatment processes.

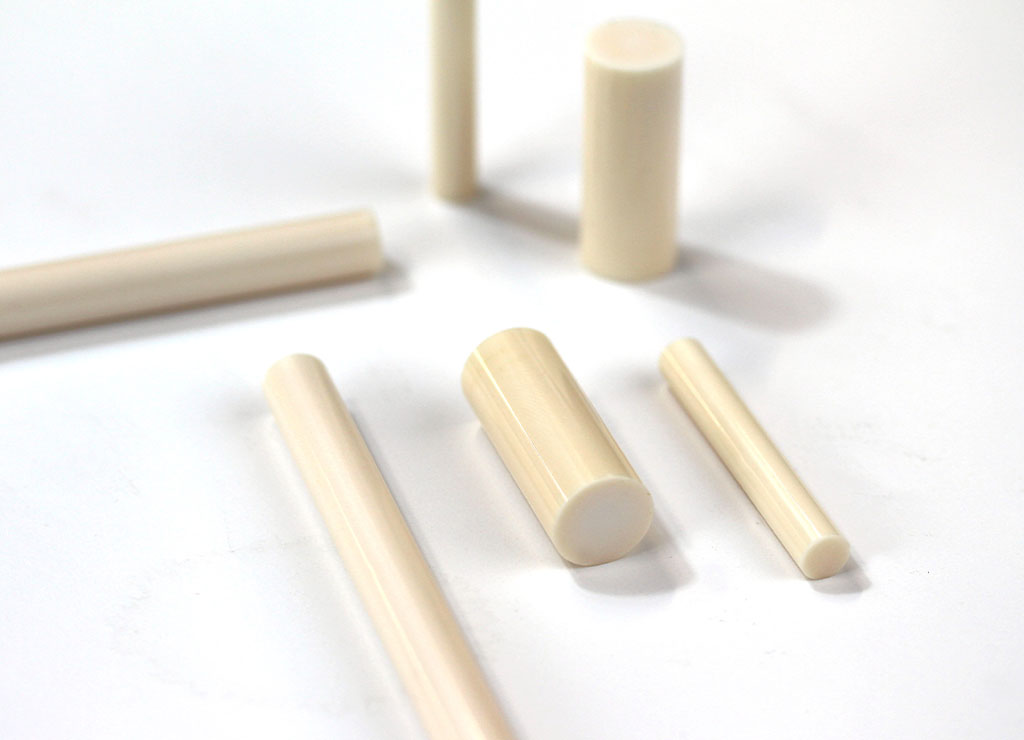

4.3 Bushings, tubes and washers with insulation functions

We produce bushings, tubes and washers that electrically isolate different parts of a system. They are used as separators or thermal barriers in assemblies where metal and current must not come into direct contact. Their high resistivity and thermal stability ensure consistent performance over time.

4.4 Complex or customized geometries for special projects

At Steelceram we develop unique parts according to the needs of each customer. We manufacture geometries that do not exist in the standard market, adapted to specific systems. From laboratory prototypes to technical solutions in production, we offer complete consultancy in the design and manufacture of complex cordierite parts.

5. Industrial sectors using cordierite manufactured by Steelceram

The cordierite parts manufactured by Steelceram are used in many sectors where thermal management and electrical insulation are essential. We work with companies involved in the production of electrical resistors, manufacturers of industrial furnaces, sintering laboratories, power electronics and thermal machinery. Cordierite is particularly valued in heating systems, inductors, furnace supports and insulating components in electrical devices. Its thermal reliability and structural stability reduce maintenance and increase equipment durability, making it an efficient, safe and technically cost-effective solution for a variety of demanding industrial environments.

6. How do we work? From the technical need to the finished part

6.1 Technical advice from the first consultation

From the first contact, our technical team accompanies the customer in the choice of material, design and feasibility of the project. We analyze the specific application and propose cordierite solutions adapted to the thermal, mechanical and electrical conditions of the environment, prioritizing functionality, cost efficiency and durability of the piece.

6.2 Design, prototyping and validation process

We start from drawings, CAD files or physical samples. We design the final geometry according to functional requirements and tolerances. We manufacture prototypes, validate them together and adjust them according to results. Only when the part fully meets expectations do we start production. This collaborative process ensures that each cordierite part performs its function with precision and reliability.

7. Conclusion: Why choose custom-made cordierite parts manufactured by Steelceram?

Working with Steelceram means working with a technical partner who understands the challenges of the industry. We offer custom cordierite parts, tailored to every need and manufactured with precision. Our technical ceramics expertise, collaborative approach and commitment to quality ensure reliable, functional and sustainable ceramic solutions for highly demanding industrial environments.